How To Bend Rebar Into A Circle

Using a manual saw to cut steel mesh. Fortunately, in building a monolithic dome only a minimum of the rebar used generally requires bending.

3 roll bender diy 4x4 and OffRoad

Thread the rebar through both pieces of pipe, allowing them to intersect at the point where you want the bend to occur.

How to bend rebar into a circle. Made a sandwich of the half circle between two uncut pieces (only one shown below) to prevent the jig from moving it was backed up against a mango tree. Our company is specializing in manufacturing and selling reinforcing bars. Cut 38 diameter half circle of 1/2 plywood as the center of my bending jig.

This jig allows me to make rings out of round or square bar, or even flat bar if needed.it uses the classic pyramid rolling bender setup but allows for thicker stock bending than the harbour freight basic machine. Depending on the size of your circle as well as forming conduit into a circle is basically the same as making one big concentric bend, which is accomplished by making several smaller bends. Put a couple of cheaters on the rebar or leave it real long and just use muscle power to bend it around the bucket.

Rebar ive used is grade 60.take your rebar find a piece of 12 pipe(3' divided by 3.14) tack your rebar to the pipe and slowly work it around the pipe putting spot tacks. Or use anything else that is round that is laying around. Tighten the vise, then slide the pipe along the other end of the rebar until it's just short of the mark.

Because the die penetrates into the sheet, pressing a dent into the workpiece. We need 2 steel pipes to bend rebar. Is it possible to bend a 6 radius into round bar without the material relaxing?

We use four benders and three coil machines to fabricate rebar in the shapes you need with exceptional precision. Lay the first pipe on the ground and slide the rebar into this pipe. Weigh the piping down on one end of the metal piping and expose the area of the rebar that you want to bend.

In order to implement the propose of serving our customers, we purchase advanced rebar bending machines to make. It is available in 20' sticks. Yet strong, and can be bent smoothly but would require professional equipment;

Now insert the second pipe on the rebar. We shear cut 20’, 30’, 40’, and standard 60’ bar stock in a range of sizes and grades to meet the needs of your project. It can't get any simpler to order sheet metal online.

From 20 years experience, we know clearly that it is inconvenient for our customers to cut and bend the straight themselves. Stress relieve with a torch ,grind tacks loose.clean as needed Later, we bend it up so that the rebar becomes included in the concrete.

1/2 is pretty easy to do. Look into something like galvanized top rail (of chain link fence.) it's much lighter weight. Idea for this concept, that feature…

Mark the point on the rebar where you want the bend to appear. Shape codes of reinforcing bars. Use leverage to lift the long piece of pipe up from the ground.

When a powered circular saw isn’t available, a manual saw will do the job. Computer automation allows us to bend #3 through #6 rebar into any shape you need. We use a rigid pipe threader machine, my teacher made a jig for it using a 2 inch pipe for the shaft and a bigger sized pipe(any size you need) welded to the shaft to make the ring guide, then you clamp the rebar to the bigger pipe w/ a vise grip and bend away using the foot pedal, but be carful cause it can get away from you if you do it to quick.

Step 1 draw a circle on the sheet metal with a pencil compass. Our welding shop bends the things down in a press, with a die and mandrel. Some old cloth was used to prevent the plywood from damaging the bark.

It's basically a big u bolt for holding down an air tank or something like that. If you need to, reheat the metal and redo the bend. Mark the position of the bend on the rebar, then insert it into the vice with the mark aligned with the jaw.

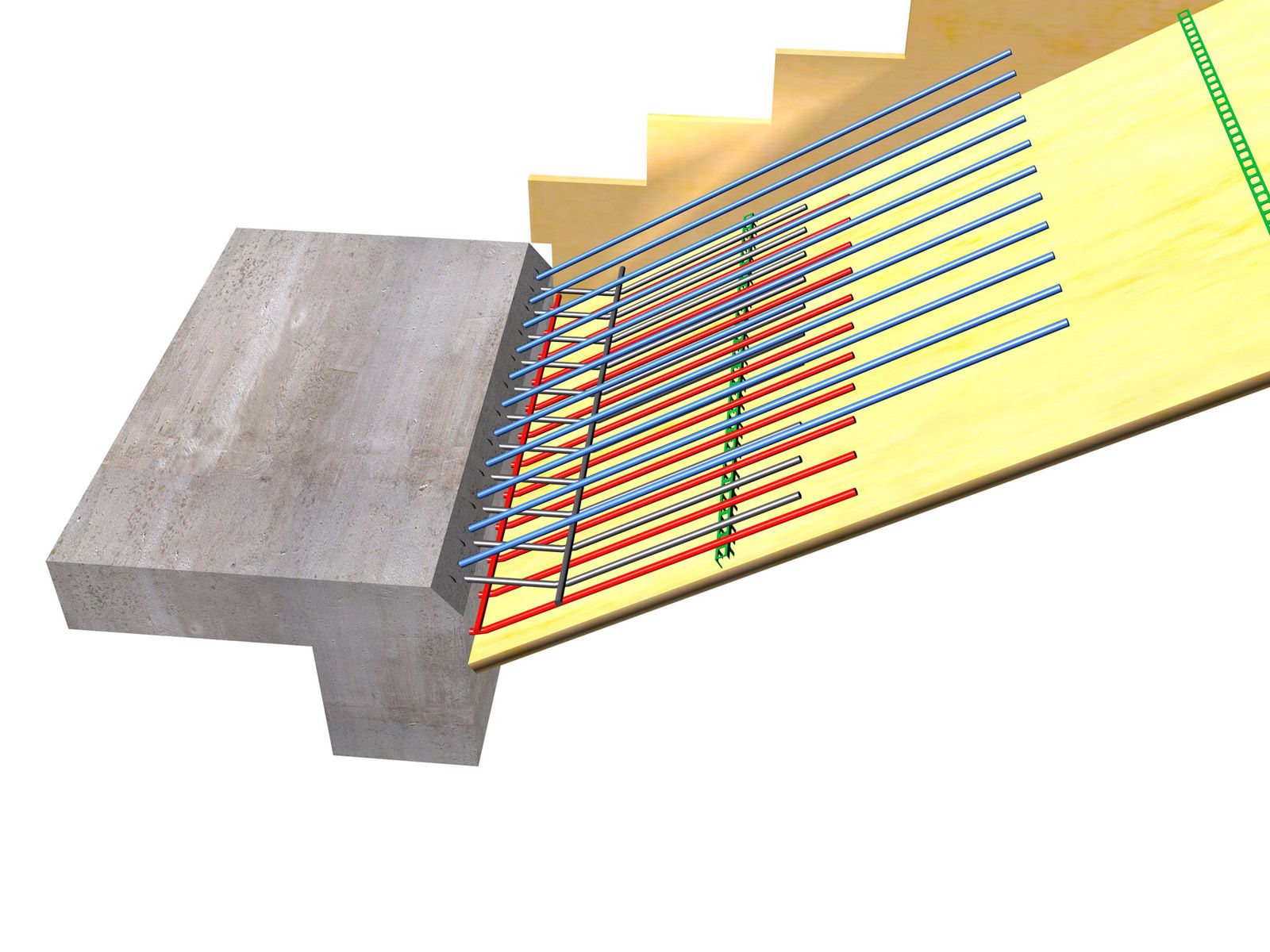

A circular saw with a metal cutting blade will offer a very quick work of any steel rebar, cutting through it with particular ease. Some welding/metalworking shops could do it. We bend the rebar embedded in the footing down to get the airform over it.

We have a customer who wants us to bend with precision a 35 long 3/8 rod of 1045 steel. There has to be a. If you only have a couple to make and the rebar is 1/2 or smaller then just fill the bucket up with sand and snap the lid on it.

Theoretically, you could make a 6' 4 circle out of a 20' stick. I am currently just heating it, and bending it around a template. Leave the mark to appear visible outside.

Mark a bend line and place the sheet metal on the edge of your bench. Place nails at all the marked locations. The diagram shows one such mechanism.

How to Bend Rebar in a Circle Rebar railing, Rustic

HOMEMADE Bending Tool for Sheet METAL REBAR

Universal bender roller, scroll, bar and profile bender

Build a Garden Archway (With images) Garden arches

Click to close image, click and drag to move. Use arrow

Нажмите, чтобы закрыть изображение, нажмите и перетащите

12V Automatic Rebar Typing Machine Rebar Tier Tool

Automatic stirrup bender machine is most reliable & time

rebar trellis archway DIY. Good instructions on how to

Bench Bar and Rod Bender Telescope, Ranges and Steel

1415 Ring Roller Metal bending tools, Metal

Automatic Wire Ring Making Machine Buy Wire Ring Making

How to Build a Jig to Bend Metal (With images

Rebar Bender Rebar, Industrial companies, Professional

Homemade Metal Bender / Ring Roller Ring roller, Metal

Post a Comment for "How To Bend Rebar Into A Circle"